The startup says it is seeing interest from US big tech players in its tech.

A Hungarian robotics hardware startup says it has raised the “highest-ever” pre-seed funding round in the country’s history.

Allonic has raised $7.2m in pre-seed funding, in a round led by Visionaries Club, with participation from Day One Capital. Other investors include angel investors from Hugging Face and OpenAI.

Allonic’s play is to speed up how robot bodies are manufactured.

It says the physical construction of robots is outdated, involving putting together robotic hands, arms and manipulators piece by piece, relying on bearings, screws, cables, and delicate joints that are costly to manufacture and tedious to assemble.

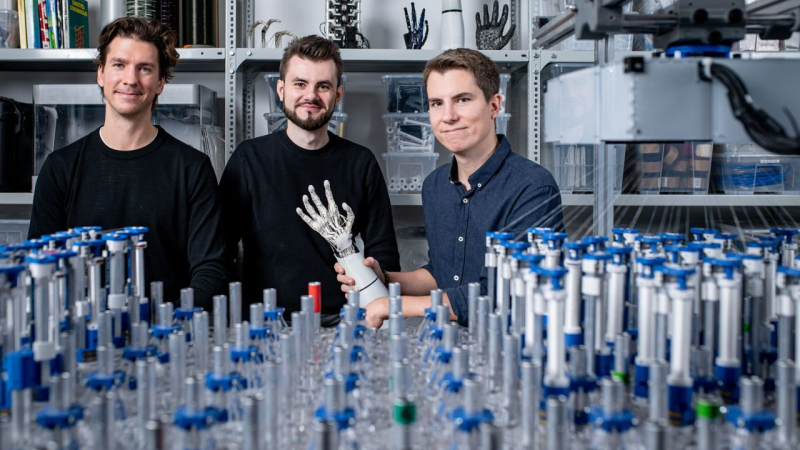

Allonic, which is a 15-strong team, is looking to disrupt the industry, taking on the challenge at the manufacturing layer.

Its proprietary production process, known as 3D Tissue Braiding, replaces manual assembly with a fully automated, scalable manufacturing system, it says.

Inspired by how ropes achieve strength through structure rather than rigid parts, Allonic 3D-weaves tailored robotic “tissues” directly over a skeletal core.

Instead of assembling hundreds of individual parts, Allonic’s tendons, joints and load-bearing soft tissues are formed together in one continuous process.

It claims its process results in robotic bodies that are “strong”, “compliant”, and simpler to manufacture.

Since revealing its technology in 2025, Allonic says it has completed its first pilot project in electronics manufacturing,

The Budapest-based startup also says it is seeing strong inbound interest from the humanoid robotics sector and large consumer technology companies, including US big tech players.

Benedek Tasi, co-founder & CEO of Allonic, said: “A lot of attention is on intelligence and software, but hardware still holds many of the hardest problems.

“The trade-offs between durability and softness, dexterity and strength have always been dictated by the limits of manufacturing.

“We are removing those constraints and building a platform that allows robotics teams to design, build and iterate freely, without hardware cost or complexity holding them back.

“Being able to go from idea to physical robot in minutes instead of weeks fundamentally changes how we can think about robotics design.”