Contents

- 1 From discovery to industrial opportunity

- 2 From investor to CEO

- 3 Why does conventional dyeing consume so much energy?

- 4 A magnet-like mechanism at room temperature

- 5 “The industry needs disruption, not nostalgia”

- 6 The environmental and economic value

- 7 Easy incorporation into existing production lines

- 8 Technical complexity and measured scaling

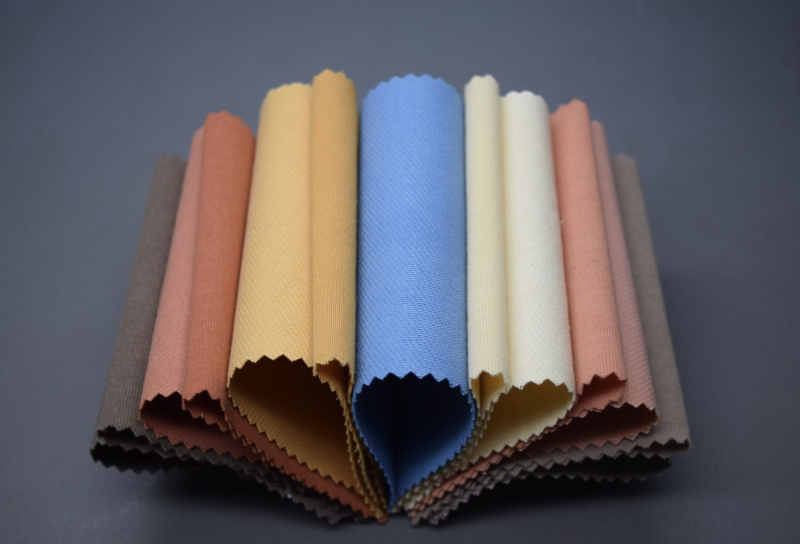

The French startup’s room-temperature dyeing technology promises up to 90 per cent lower energy use, cleaner wastewater, and cost parity with petrochemical dyes.

Behind every brightly coloured garment lies a largely invisible cost. Dyeing synthetic fibres can account for up to 60 per cent of the total energy used in textile production, while the global dyeing industry is responsible for nearly 20 per cent of water contamination and around 5 per cent of greenhouse-gas emissions.

In a sector built on heat-intensive petrochemical chemistry, French startup Everdye believes it has found a radically different path.

The company has developed a new dyeing process that can cut energy consumption by up to 8x — without requiring dye houses to overhaul their machinery.

I spoke to CEO Philippe Berlan and CTO Dr Amira Erokh to learn more.

From discovery to industrial opportunity

Everdye’s founding traces back to the doctoral research of co-founder Dr Amira Erokh. During her PhD, conducted across universities in Tunisia, Portugal, and France, she participated in a NATO-backed project to develop fabrics resistant to biological attack.

CEO, Philippe Berlan, explains:

“During that research, she made a discovery that wasn’t part of the original objective. At the time, she didn’t yet know what the practical application could be, but the chemistry behind it later became the foundation of Everdye.”

After completing her PhD, Erokh worked in the paint industry in Tunisia before relocating to France for personal reasons. There, she joined an entrepreneurship programme that helped her translate scientific insight into an industrial opportunity.

Through extensive conversations with textile industry collaborators, she realised her chemistry could be adapted for dyeing. She began experimenting at home — literally in her laundry room — building the first working prototype there.

Everdye was formally founded in 2021, secured early funding in 2022, and began structuring its industrial development soon after.

From investor to CEO

Berlan initially joined the company as an investor before stepping in as CEO.

“When the team needed more senior management with industry experience, it made sense for me to step in. I came from the fashion and textile world, so joining Everdye was a way to help transform the industry from the inside.”

Why does conventional dyeing consume so much energy?

Traditional textile dyeing relies on forcing chemical bonds between dye molecules and fibres. These strong carbon bonds do not form spontaneously.

To make the reaction happen, manufacturers use high heat — often around 130°C — along with petrochemical-based auxiliaries. Deep colours such as black can require six to seven hours of processing.

Berlan explained:

“This heavy heating leads to enormous energy consumption and large greenhouse gas emissions.

At the same time, the dye bath becomes contaminated with toxic residues, and in many regions wastewater is released directly into rivers or oceans without proper treatment.”

The environmental burden is therefore twofold: high emissions from heating, and water pollution from chemical discharge.

A magnet-like mechanism at room temperature

Everdye’s process takes a fundamentally different approach to traditional dying. During the standard bleaching step — required before dyeing — fibres naturally develop negatively charged sites. Instead of counteracting that chemistry, Everdye harnesses it.

Everdye’s pigment functions almost like a magnet. A pretreatment creates negatively charged anchoring points on the fibres’ surfaces; the pigment, which carries a positive charge, instantly locks onto these points. Through electrostatic attraction, the pigment naturally attaches to the fibre at room temperature.

Then, during the drying stage — already part of any dyeing process — polymerisation locks the pigment permanently into the fibre. The final attachment strength is comparable to that of conventional dyeing, without the need for prolonged high heat or toxic chemical additives.

“The industry needs disruption, not nostalgia”

Before petrochemical dyes, textiles were coloured using natural pigments derived from plants, insects, and minerals. While these methods were less industrially intensive, they were difficult to scale and often lacked durability. Berlan is clear that Everdye is not attempting to revive historical techniques.

“When petrochemical dyes appeared, they solved the performance problem. They delivered strong, stable colours at an industrial scale. At the time, the environmental consequences were not understood.

Today, the entire textile industry is built around that petrochemical model. Our goal is not to go backwards to historical dyeing. We are creating a new chemistry that combines industrial-quality performance with a radically lower environmental footprint. The industry needs disruption, not nostalgia.”

The environmental and economic value

Everdye’s modelling shows energy reductions of 80–90 per cent compared to conventional dyeing. Production cycles can be three to four times faster. Toxic wastewater treatment is largely eliminated. Depending on the benchmark process, greenhouse-gas emissions can be reduced by 60 per cent to nearly 99 per cent.

Unlike conventional methods that rely on hours of high-temperature treatment, Everdye’s process works rapidly at ambient temperature, significantly reducing both energy costs and greenhouse-gas emissions. All pigments developed by the company are bio-sourced, produced exclusively from plant-based or mineral raw materials. The result is almost clean water at the end of the dyeing cycle.

This delivers several major advantages:

- A massive reduction in water and energy consumption.

- Fewer chemical residues.

- Richer, longer-lasting colour.

- A simplified dyeing process.

Long-term, cost parity is central to the strategy.

“Our objective is cost parity,” explained Berlan.

“Today green solutions often carry a premium. As we scale production, pigment prices will fall, while operational savings — energy, labour, and water treatment — rebalance the economics.”

The total process becomes competitive, not just environmentally but financially.

Easy incorporation into existing production lines

The startup’s primary customers are dye houses. The market is highly fragmented globally, so the company is focusing first on Europe to strengthen the technology and gain operational experience before expanding. A critical advantage is that no new capital equipment is required. Berlan explains:

“Dye houses don’t need capital investment. They simply adjust process parameters. With minimal training, they can integrate the technology into their existing production lines.”

The company also collaborates directly with apparel brands facing increasing pressure to decarbonise supply chains.

Technical complexity and measured scaling

Textile dyeing is among the most technically complex manufacturing processes. Different fibres, colours, and machine types each represent separate technical variables that must be validated independently.

“Textile dyeing is extremely complex. You have different fibres, colours, and machinery types — each combination is a separate technical challenge,” says Berlan.

Everdye currently offers primary colours, enabling a wide range of shades. Deep black — one of the most technically demanding pigments — remains under development. The pigments are already ready for cellulosic fibres such as cotton, hemp, and linen. Polyester — the world’s most widely used fibre — is in advanced development. The company supports garment dyeing and roll dyeing, while a soluble pigment format for jet dyeing is being developed with strategic partners.

The focus is on reliability over speed.

“The priority is quality and reliability. We want smooth adoption and industrial confidence. Entering this market requires delivering consistent performance.”

According to Berlan, the biggest barrier facing the sector is cultural and financial rather than technical.

“This is a traditional industry, and change takes time. Factories operate on long-established processes and spreadsheets that favour legacy systems.”

But the environmental and social cost of current dyeing practices is becoming impossible to ignore. Many communities are directly harmed by toxic discharge. The pressure to transform is increasing from regulators, brands, and consumers, and EverDye offers a viable way forward.

Lead image: Everdye CEO Philippe Berlan and CTO Dr Amira Erokh.